How manufacturers and engineering firms benefit from bespoke system

If there's one thing manufacturers and engineering firms know, it's that the key to success is making custom-made products. That's why bespoke system software is so important - it helps them create unique solutions for their clients. By tailoring the software to their specific needs, they can ensure that their products are totally unique and precisely suited to the client's needs. Not only does this make the client happy, but it also sets these firms apart from their competitors. So if you're looking for a manufacturing or engineering firm that can deliver the goods, be sure to ask about their bespoke system capabilities!

You will often find that manufacturers and engineering firms have huge amounts of products, materials, and general inventory changings hands every day. So why is it that there are such limited options in the form of pre-made off-the-shelf software?

The answer is due to the nature of the industry itself. There are many companies, businesses, factories and the like that are simply too unique to fit into the boxes provided with off-the-shelf software.

That’s not to say there aren’t some companies who can find a perfect fit for them pre-made elsewhere, but for the vast majority of you, it’s going to be hard to find software that allows you to integrate your existing workflows and ways into it without any hassle.

We have created Custom Engineering Software for a company, ESI Controls Limited and now they are using our software for Manufacturing and Distributor of Heating Control Components. They were using Spreadsheets to manage their orders, leads and sales earlier.

So how is bespoke software different?

It’s not uncommon to find companies and businesses that have existing workflows and frameworks in place, bespoke software is brilliant in the way it can keep these flows in principal but with the addition of efficiency.

Since bespoke software is completely flexible and works exactly the way you want and envision it, anything can be done, all in one place. These customisable systems allows clients to use online portals to access what they need quite easily.

What processes can be done with bespoke software?

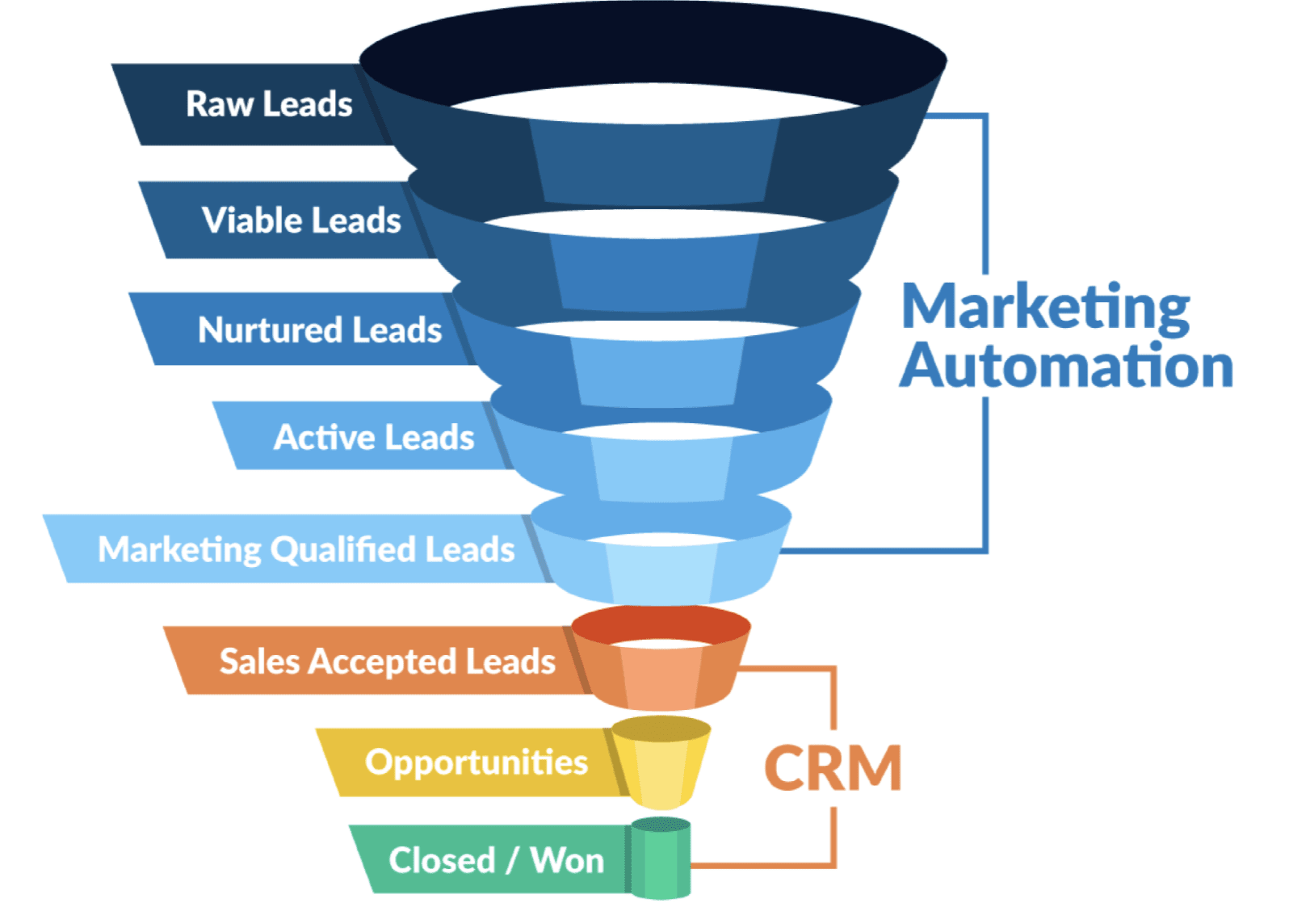

- Enquiries to invoicing

- Take enquiries, leads, quoting and invoicing for example. Lots of companies will do these across multiple different pieces of software all stitched together, perhaps using one prospecting CRM to manage their leads and then another financial based system to generate quotes, and finally another system to take payments or send invoices. With a bespoke system, all these features can be built into one.

- More automation can then be used as certain fields can be drawn from existing records saving you time and accuracy entering data across multiple platforms.

- Communication

- One of the main complaints we here at Web Alliance come across from manufacturers is the clear disconnect between the sales and production teams.

- With bespoke software it can be made explicitly clear exactly what is happening so all team members are exactly up to date with the inner workings of the company in real-time. As a result, there is a much slimmer chance of any decrease in efficiency due to simple miscommunication.

- Inventory management

- Tying in with the above point, taking control of what you have in stock is a game changer for warehouse and storage management.

- Boasting a plethora of features including, (but not limited to) knowing what you have in stock, setting re-order levels, tracking expenditure and profit as well as forecasting demand of products, is a huge reason why companies with their own tailor-made software tend to do so well in predicting and staying on top of supply and demand, a fundamental for any manufacturer.

- Reports and KPI’s

- Finally reporting and KPI’s are a huge indicator as to how well your company is doing.

- Whether that’s sales reports, marketing, or even inventory, its always best to stay on top of all the data that can be analysed within your business

So, is bespoke right for me?

The only person who can truly answer that question is you! However, the good thing is, you don’t have to make that decision all alone. If you are considering investing into a bespoke system for your business, please feel free to get in touch for a free, no obligations, 1 to 1.

So, do engineering companies need custom software? The answer is a resounding yes. Custom software can help connect production and inventory, speeding up the manufacturing process and helping to keep everything streamlined. If you’re looking for ways to improve your production process, bespoke software may be the answer you’ve been searching for. To learn more about how we can create a custom solution tailored specifically to your needs, get in touch with us today. We would be happy to discuss our services with you and see how we can help streamline your manufacturing process.

FAQs

Q. What is a bespoke system and how does it differ from off-the-shelf solutions?

Q. Why should manufacturers and engineering firms consider investing in bespoke systems?

Q. What are the long-term benefits of implementing bespoke systems in manufacturing and engineering?

Q. How does the development process of a bespoke system work for a manufacturing or engineering firm?

Q. Are there any challenges associated with bespoke systems that firms should be aware of?

Related Blogs

8 Ways a Custom Database System Will Expand the Growth and Success of Your Business

Did you know that custom databases are more practical and …